Räuber

Established

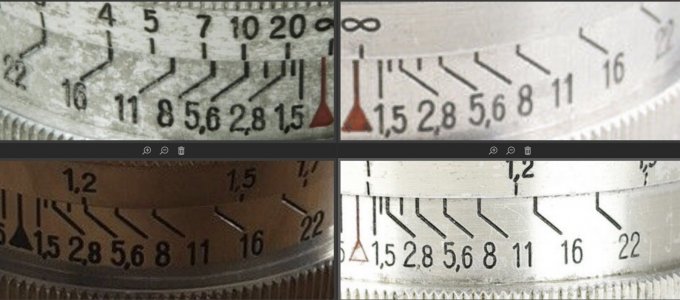

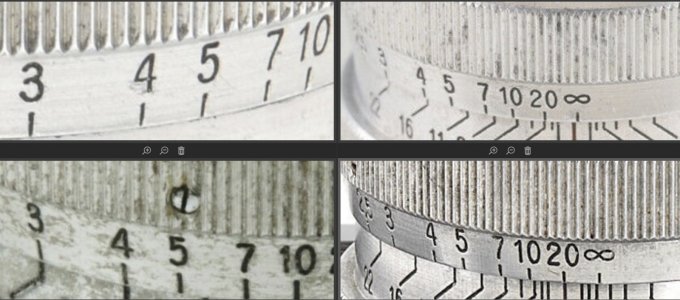

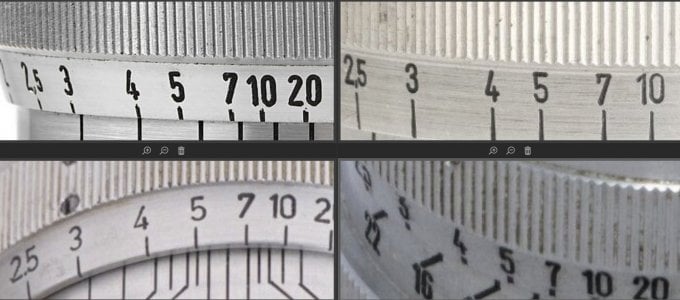

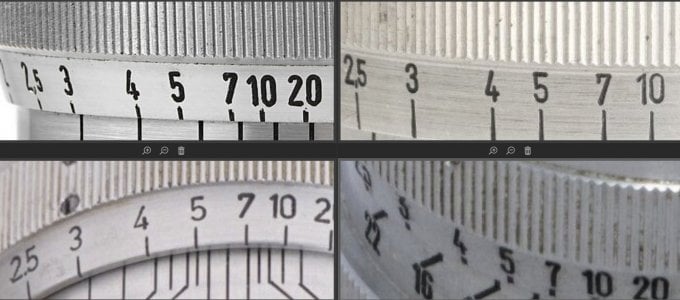

By accident I stumbled over some detail that might help to date LTM Sonnar 5cm f/1,5. I noticed different fonts that where used at different versions.

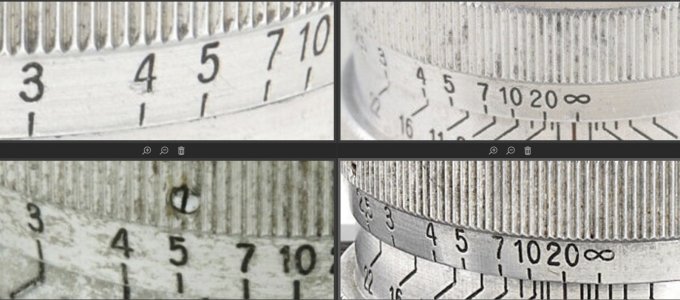

It is a theory for now but I would like to share my findings. You can differentiate the origin of a LTM Sonnar 5cm f/1,5 through looking at the focus scale especially the numbers 3, 4, 5, 7.

CZJ wartime Sonnar 5cm f/1,5 T (authentic / 1940+)

prewar Sonnar 5cm f/1,5 T (red dot / transition / 1944+)

KMZ Jupiter-3 5cm f/1,5 P (1951+)

It is easy to see that the 4 changes its appearance over those periods. The 7 is also a very good indicator of the origin of the lens. While during war the seven hat not small caps and a light bow in the long side, it got small caps in the transition time after the war and the long side changed to a straight line. The Soviet 7 only consists of 2 straight lines.

I found some interesting observations after noticing the numbers of the focusing scale.

Here is one with an inverted focusing scale -> Transition fonts

Then there is one of Skyllaneys refurbished lenses -> Transition fonts

Then there is one of those rare East German CZJ LTM Sonnars -> Transition fonts

And then there is my own LTM wartime CZJ Sonnar 5cm f/1,5 -> unique 3 & 4 🙈 🥲

Damn, now I have to find a better example for the overview. More money to burn...

It is a theory for now but I would like to share my findings. You can differentiate the origin of a LTM Sonnar 5cm f/1,5 through looking at the focus scale especially the numbers 3, 4, 5, 7.

CZJ wartime Sonnar 5cm f/1,5 T (authentic / 1940+)

prewar Sonnar 5cm f/1,5 T (red dot / transition / 1944+)

KMZ Jupiter-3 5cm f/1,5 P (1951+)

It is easy to see that the 4 changes its appearance over those periods. The 7 is also a very good indicator of the origin of the lens. While during war the seven hat not small caps and a light bow in the long side, it got small caps in the transition time after the war and the long side changed to a straight line. The Soviet 7 only consists of 2 straight lines.

I found some interesting observations after noticing the numbers of the focusing scale.

Here is one with an inverted focusing scale -> Transition fonts

Then there is one of Skyllaneys refurbished lenses -> Transition fonts

Then there is one of those rare East German CZJ LTM Sonnars -> Transition fonts

And then there is my own LTM wartime CZJ Sonnar 5cm f/1,5 -> unique 3 & 4 🙈 🥲

Damn, now I have to find a better example for the overview. More money to burn...

Last edited:

Räuber

Established

Räuber

Established

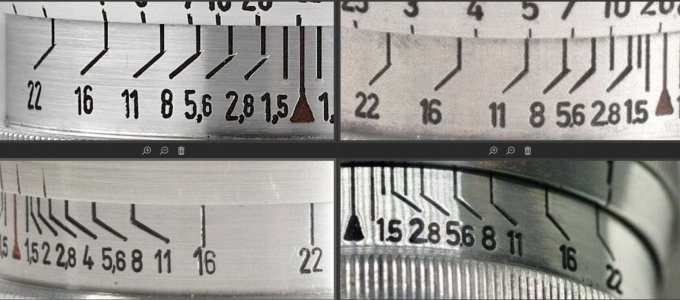

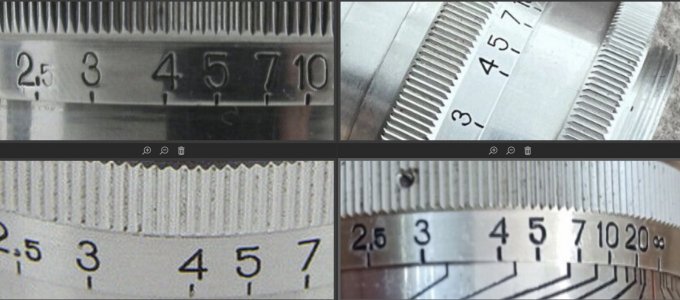

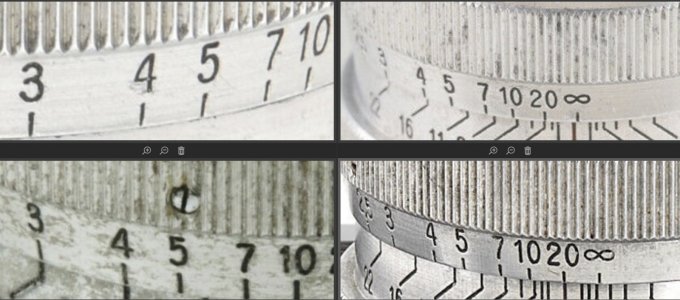

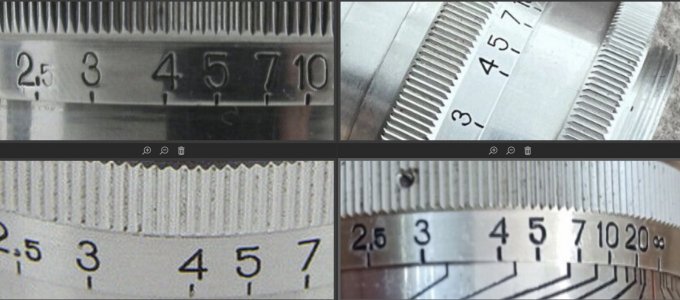

The last bit is the aperture scale of the LTM Sonnar 5cm f/1,5.

CZJ wartime Sonnar 5cm f/1,5 T (authentic / 1940+)

Post-war Sonnar 5cm f/1,5 T (red dot / transition / 1944+)

KMZ Jupiter-3 5cm f/1,5 P (1951+)

You can might see something through the given examples from different periods of production.

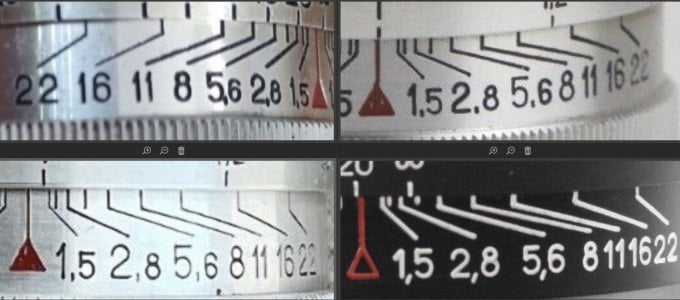

The big mystery here are the transition lenses. It is still to early to jump to conclusions. What we can see here could be spotty production quality after a devastating war. It could be different lens manufacturers or employees manufacturing illegally copies. For me it does not look like that the Jupiter production is the main source of those transition lenses. It looks more like Jena itself.

There are more interesting examples. This one bothers me most:

The shown Not-Fake example is a transition lens. The shown fake is more authentic than the other one. All the talk about dots and commas at this page lead me to wrong conclusions and I still check for dots in fractional numbers...

This page shows another transition lens. This is a real unique one. It has a red arrow as aperture mark and some kind of zick-zack distance scale.

This one amazed me with the comma separator in the aperture scale. Never seen such sharp commas at another Sonnar lens. Those numbers are tiny. It might be a unique transition lens but the craftsman engraving it had amazing skills.

CZJ wartime Sonnar 5cm f/1,5 T (authentic / 1940+)

Post-war Sonnar 5cm f/1,5 T (red dot / transition / 1944+)

KMZ Jupiter-3 5cm f/1,5 P (1951+)

You can might see something through the given examples from different periods of production.

- Scales during WWII and in Soviet production always use commas for numbers.

- Scales during WWII and in Soviet production mostly use the same fonts and typeset.

- During the transition time after WWII and the start of Soviet production there were a lot more variation. The comma sometimes was replaced by a dot. Lines of scales where sometimes very unclean and differed from lens to lens.

- In the transition time the fonts got a tiny bit smaller and cleaner. The Jupiter production used a different font than the previous periods. The letters where a little bit taller.

The big mystery here are the transition lenses. It is still to early to jump to conclusions. What we can see here could be spotty production quality after a devastating war. It could be different lens manufacturers or employees manufacturing illegally copies. For me it does not look like that the Jupiter production is the main source of those transition lenses. It looks more like Jena itself.

There are more interesting examples. This one bothers me most:

How to avoid Zeiss/ Sonnar fakes

Zeiss Sonnar f/2, 85mm, Jupiter, Russian lenses, Carl Zeiss Jena, Sonnar, Planar, f/1.5, 1.5/50mm, 1.5/5cm

www.klassik-cameras.de

The shown Not-Fake example is a transition lens. The shown fake is more authentic than the other one. All the talk about dots and commas at this page lead me to wrong conclusions and I still check for dots in fractional numbers...

This page shows another transition lens. This is a real unique one. It has a red arrow as aperture mark and some kind of zick-zack distance scale.

This one amazed me with the comma separator in the aperture scale. Never seen such sharp commas at another Sonnar lens. Those numbers are tiny. It might be a unique transition lens but the craftsman engraving it had amazing skills.

Last edited by a moderator:

Thankyou for this! I've seen several custom converted LTM Sonnars, going back to when they were new. Some real craftsman making custom fixtures. I've seen a custom conversion done by Cook & Perkins- someone must have wanted a custom mount, rather than their adapter.

Räuber

Established

I noticed 2 mistakes.

When I talk of fakes I might sound a little unfair because I know that in a lot of cases the lenses used by the "fake" where created by CZJ. Sometimes the resulting fake is a real work of craftsmanship. If in 1945 someone owned a Contax Sonnar 5cm f/1,5 and wanted to sell it for some Dollars he went to a workshop and they created an LTM Sonnar out of this Contax Sonnar. On the black market this Sonnar now was more valuable than before and should soon have found a new owner. In this case the lens is still a CZJ lens inside. So is this fake? I dunno.

I struggle how to call those lenses. Transition lens might be a good name but not a lot of people know what this would mean.

And then nobody knows what to expect from such a lens. It could be the best lens you have ever used. Or it could be the worst. 😄 Brian knows tons of stories of unfinished or not working transition Sonnars. It is a gamble.

The above information might shine some light on the backgrounds and might help to identify Sonnars that were customized in some way. I'm working on a more detailed overview of this matter at the moment. Will share it when it is finished.

- the word prewar in the subtitles is wrong. I meant post-war lenses. All examples are from LTM Sonnar 5cm f/1,5 with a red dot as aperture mark. I know there are a lot more different transition variations but the ones that looks quite similar to the war time CZJ Sonnars but have a red spot as aperture mark might be the biggest group of "fakes".

- In the examples of aperture rings from transition lenses the top left example only reaches f11. I should have excluded this example. It looks like the one that created this lens just used a pre-war Chrome Sonnar. The example shows the original aperture ring of the lens that was housed into a transition body.

When I talk of fakes I might sound a little unfair because I know that in a lot of cases the lenses used by the "fake" where created by CZJ. Sometimes the resulting fake is a real work of craftsmanship. If in 1945 someone owned a Contax Sonnar 5cm f/1,5 and wanted to sell it for some Dollars he went to a workshop and they created an LTM Sonnar out of this Contax Sonnar. On the black market this Sonnar now was more valuable than before and should soon have found a new owner. In this case the lens is still a CZJ lens inside. So is this fake? I dunno.

I struggle how to call those lenses. Transition lens might be a good name but not a lot of people know what this would mean.

And then nobody knows what to expect from such a lens. It could be the best lens you have ever used. Or it could be the worst. 😄 Brian knows tons of stories of unfinished or not working transition Sonnars. It is a gamble.

The above information might shine some light on the backgrounds and might help to identify Sonnars that were customized in some way. I'm working on a more detailed overview of this matter at the moment. Will share it when it is finished.

I changed "Pre-War" to "Post-war" for you, RFF members with 250 posts can do this themselves.

This means you need to keep putting up more of these great posts....

This means you need to keep putting up more of these great posts....

oldhaven

Member

I don’t think I am going too far off topic, but I ran an industrial engraving shop out of my home for 20 years, so this subject interests me. Here are some pictures that show some of the types of tools used for these engraved parts. The dial shown, on a very late Kiev 4M I have, is an example of what happens when an engraver doesn’t care much about his or her work. The numbers look distorted and the arrow isn’t even recognizable The single point tool used for this work is sharpened to a point that can be as small as .003 to .010 thousandths of an inch. You can see what a fine point that is in another picture. This cutter is placed in a pantograph engraving machine spindle and rotates at over 10000 rpm and up to 18000 rpm depending on the material. The depth of cut is probably around .010” in these camera parts. So you can see that as you go deeper the cut gets wider. The hand controlled depth of the cutter is finely controlled by the left hand so some finesse in shaping the look of the letter or number is possible. If the tool gets even slightly dull it starts to wander in the material as the fine point is bent by the drag of the dull cutter. In addition, depending on the alloy, aluminum is rather “gummy” and can pull a cutter off course. I think this dial is a good example of a worker being lazy about sharpening or changing the cutter in his machine. I have worked on jobs where I had to resharpen cutters every couple of minutes to make a presentable job. The machine shown is a Gorton, but before I sold most of my equipment I had a couple of pre war Deckel engravers, and it is likely that the spoils of war taken to the Soviet Union were the machines used in Germany prior to and during the war. These were incredibly tough and accurate engravers, and did not tend to wear out if properly maintained.

The other possible cause of poor engraving is the wear of the templates used for lettering. These were generally brass and the stylus used with them is hardened steel as is shown here. I sold my brass numbers and letters, but here is an example of letters and a fancy template made of hard Formica. As for the fine work shown by the commas on these dials, that was no doubt done by an engraver who took some pride and could finely control the cutter so that raising it as the comma's tail was made could get the cutter tip to a few thousandths width, while the fat part of the comma was cut deeper.

I also want to mention that unless very sophisticated fixturing is used, engraving a lens dial that is round and tapered is very time consuming exacting work requiring a lot of coordination and skill. I would love to see some factory pictures of the process.

The other possible cause of poor engraving is the wear of the templates used for lettering. These were generally brass and the stylus used with them is hardened steel as is shown here. I sold my brass numbers and letters, but here is an example of letters and a fancy template made of hard Formica. As for the fine work shown by the commas on these dials, that was no doubt done by an engraver who took some pride and could finely control the cutter so that raising it as the comma's tail was made could get the cutter tip to a few thousandths width, while the fat part of the comma was cut deeper.

I also want to mention that unless very sophisticated fixturing is used, engraving a lens dial that is round and tapered is very time consuming exacting work requiring a lot of coordination and skill. I would love to see some factory pictures of the process.

Last edited:

Räuber

Established

You can find some images of the workers at Carl Zeiss Jena form the 1950ies at Zeissikonveb. At that time a lot of young women were working there.

zeissikonveb.de

zeissikonveb.de

zeissikonveb.de

zeissikonveb.de

Pronto, presto, subito! | zeissikonveb.de

Zentralverschlüsse im Kamerabau der DDR. Velax, Binor, Priomat, Ovus, Cludor, Vebur, Tempor, Prestor, Compur.

zeissikonveb.de

zeissikonveb.de

Contax und Pentacon | zeissikonveb.de

Zeiss Ikon, Contax S, Spiegel-Contax, Pentacon camera, Wilhelm Winzenburg, Contax D, Spiegelcontax

zeissikonveb.de

zeissikonveb.de

oldhaven

Member

Thank you for the links to the articles, I really like the image of a young lady doing five focus or aperture rings at once from a single long template. I had a Deckel similar to the one in the black and white photo of the lady doing a single ring. You can see her left hand controlling the cutter depth at the spindle. She is using a rotary table and has to do one number every few degrees. Obviously the color picture shows quite a bit of improvement in technology. I am surprised that there are no safety glasses since the tiny metal swarf pieces are very sharp and come off the cutter at high speed and can travel several feet. Wonderful pictures.

Zuiko-logist

Well-known

The photos could have been staged, hence no safety glasses. Nevertheless, the high speed lathe looks dangerous!

Lovely photos. Would they be late 1959s into 1960s era?

Lovely photos. Would they be late 1959s into 1960s era?

Share:

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.