Räuber

Established

Yes, I use Excel lists to collect all Sonnars 5cm I can find. I have learned one or two things from this lists. 😄That's interesting! I assume you counted the reflections to arrive at these figures?

I guess it makes sense, since nearing the end of the war the material shortages must have been severa and Zeiss was emptying out the drawers and bins for anything to make lenses out of in order to meet the designated quotas.

It is not only shortage of supply that caused big issues. Zeiss heavily relied on replacement workers since a huge part of the (mostly) male workers that where working in the factory before the war where send or went unsolicited to the Wehrmacht and where fighting and dying in this bloody war. During WWII CZJ employed 8.100 and Schott 3.500 forced labourer. Those people where not trained or skilled craftsmen but worked and lived under hard conditions.

With the start of WWII the build quality of Sonnar lenses started to drop compared to previous versions. Parts of lenses where made from cheap metal, dimensions of parts start to vary and the failure rate went up. And then the rate of hacked Sonnars is the biggest issue during this years.

raid

Dad Photographer

I wonder if I even own one "rare" lens!

You donated a very rare lens to the Museum.I wonder if I even own one "rare" lens!

The most rare/expensive lens I own was never used for photography, was used for an Optical Computer for Fourier Transforms, made in the early 1980s. Cost $40K. I pulled it from a dumpster when it was being thrown out as bulk trash.

raid

Dad Photographer

Actually, I donated a WWII camera and several lenses for it to the Naval Aviation Museum. You are right, Brian.

It was Camera Number XI out of 13 3-D cameras made by Douglas Winnek. I wanted it safe at a reputable museum.

It was used during WWII to do surveillance of Japan for choosing the target cities for the A-bombs.

It was Camera Number XI out of 13 3-D cameras made by Douglas Winnek. I wanted it safe at a reputable museum.

It was used during WWII to do surveillance of Japan for choosing the target cities for the A-bombs.

JakobN

JakobN

Räuber wrote: "There are still 2500 Contax missing". Maybe they never existed. No 53 is not real, these numbers are part of no 52 and numbers 62,70 and 71 are not documented in the Zeiss archive.Thank you Brian. Hacked is a good word for a lot of those WWII Sonnar lenses. It is a lot shorter than Frankenstein. 😄

About that missing lenses from WWII... I looked up my Excel sheets again and I think it is fine. There is no major issue here. It is WWII...

Those prototype ones can be ignored since they will not show up anyway. A lot of ARRI Sonnars went missing but this is no surprise since those would be more likely be used at the battlefront of WWII and since ARRI Sonnars are not very searched for today. The Super Parvo batch is very small and the system is not very common today so those are extremely rare to find. There are still 2500 Contax missing. Brian you will likely have seen some of those batches. Quite a lot will suffer hacking done during and after the war. Some will suffer quality issues through Zeiss struggling with supply and replacement workers. Some might be what you call transition Sonnar lenses.

- 47, 48, 49 = prototype batches of single or 2 lenses to test Super Parvo or ARRI

- 50 = 100 ARRI (1 hacked seen)

- 53 = 600 Contax

- 55 = 300 ARRI

- 57 = 100 Super Parvo

- 59 = 1 Contax (maybe prototype)

- 60 = 150 ARRI

- 62 = 800 Contax

- 66 = 60 ARRI

- 68 = 2000 Leica (1 seen)

- 70 = 1000 Contax

- 71 = 100 Contax

Looking at the few published production cards from the archive I believe the date under "Fertig." in Thiele's lists is the day the grinding of the lens sets was finished. Later the objectives would be assembled, at least in most cases.

So in "Thiele" we can see what specific lens sets have been produced and when, but we cannot see whether they were finished as the intended product, mounted for an other purpose or never used at all.

Räuber

Established

That are my thoughts too. It seem like no coincidence that all batches with no lenses found yet are all those that where reconstructed by Mr. Thiele. So there was no production card.Räuber wrote: "There are still 2500 Contax missing". Maybe they never existed. No 53 is not real, these numbers are part of no 52 and numbers 62,70 and 71 are not documented in the Zeiss archive.

Looking at the few published production cards from the archive I believe the date under "Fertig." in Thiele's lists is the day the grinding of the lens sets was finished. Later the objectives would be assembled, at least in most cases.

So in "Thiele" we can see what specific lens sets have been produced and when, but we cannot see whether they were finished as the intended product, mounted for an other purpose or never used at all.

Fertig. simply means production and Mr. Thiele was interpreting this date as day when production of the batch started (with the first lens of this batch). It is an interesting thought that this date means that the grinding of the lens has been already finished at this point. I have no evidence if the lens grinding started at this day or finished at this day. But I can share some details.

- Those production cards where a kind of order. Most batches where created by orders of lenses to be bundled with cameras. For example Zeiss Ikon would order a batch of 500 Sonnar 5cm F/1.5 for their next lot of 500 Contax II cameras. It was not common to produce a camera without lens or a standard lens without camera. It is not like today that Zeiss is producing 1000 C Sonnar 50mm F/1.5 T* for photo shops.

- The optical calculation never changed within a batch. But the design of the lens was changed during some batches. Even the switch to single coating was done during batch 43 and 45. That hints that both batches where produced in parallel.

JakobN

JakobN

No, I do not have access to the Zeiss Archive, I am just referring to Thiele's publication of it.That are my thoughts too. It seem like no coincidence that all batches with no lenses found yet are all those that where reconstructed by Mr. Thiele. So there was no production card.

Fertig. simply means production and Mr. Thiele was interpreting this date as day when production of the batch started (with the first lens of this batch). It is an interesting thought that this date means that the grinding of the lens has been already finished at this point. I have no evidence if the lens grinding started at this day or finished at this day. But I can share some details.

@JakobN When you write about the Zeiss archive what do you mean by that? Do you mean the real Zeiss archive? Is it possible to look into their production documents?

- Those production cards where a kind of order. Most batches where created by orders of lenses to be bundled with cameras. For example Zeiss Ikon would order a batch of 500 Sonnar 5cm F/1.5 for their next lot of 500 Contax II cameras. It was not common to produce a camera without lens or a standard lens without camera. It is not like today that Zeiss is producing 1000 C Sonnar 50mm F/1.5 T* for photo shops.

- The optical calculation never changed within a batch. But the design of the lens was changed during some batches. Even the switch to single coating was done during batch 43 and 45. That hints that both batches where produced in parallel.

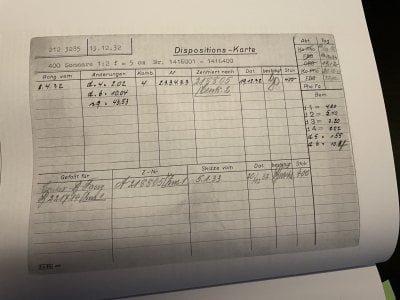

I am aware of Thiele's interpretention of "Fertig.", but when I look at the cards reproduced (one in Fabrikationsbuch CZJ II and six in Lawrence Gubas' Zeiss and Photography) it seems to me that the upper half of the card concerns the grinding of the lenses starting with the indication of what computation to use and ending with a signature confirming that the ordered number has been produced. My guess is that all the lenses of an order were made in one go, kept in stock and used according to demand. For instance sets of Sonnar 1.5 could end both as Contax lenses and Contaflex lenses.

Räuber

Established

Very interesting. I never bothered to investigate the sample of production card but maybe we can learn something from it.No, I do not have access to the Zeiss Archive, I am just referring to Thiele's publication of it.

I am aware of Thiele's interpretention of "Fertig.", but when I look at the cards reproduced (one in Fabrikationsbuch CZJ II and six in Lawrence Gubas' Zeiss and Photography) it seems to me that the upper half of the card concerns the grinding of the lenses starting with the indication of what computation to use and ending with a signature confirming that the ordered number has been produced. My guess is that all the lenses of an order were made in one go, kept in stock and used according to demand. For instance sets of Sonnar 1.5 could end both as Contax lenses and Contaflex lenses.

This cards are made to take an order for one lens and than document all phases of production until the finished lenses are delivered.

- the order is for 400 Sonnar 5cm F2

- the serial number range is that of the 8th batch of the F2 Sonnar

- the order was received at Tuesday 13.12.32

- on 14.12.32 the order arrived at department Ko Pho (Konstruktion Photo? construction photo?)

- on Friday 16.12.32 the order arrives at department FBB (F-Betriebsbüro, frame-operations office?)

- on Monday 19.12.32 the order arrives at department OBB (O-Betreibsbüro, optics-operation office?)

- 400 finished kits of grinded Sonnar lenses are handed out (thats the date from Thiele Nummernbuch)

- on 20.12.32 the manufacturing of 400 Sonnar lenses is started (this is the date that belongs in Thiele Nummernbuch)

Interestingly the date for Pho Fa (Photo Fasserei, photo assembly) is missing. But we know that all lenses where assembled.

The most interesting thing for me is the Skizze vom entry. It says 5.1.1933 and that means this is some weeks after production of the lenses started. Skizze vom means sketch from. It means the sketch with the details how the lens is constructed was provided after the start. This is in line with what can be observed online. The design of the Sonnar 5cm F2 changed from batch 7 to batch 8. For example the engraved F-number switched from F22 to F16. So they did not use the old sketch but a new sketch was handed the lens workshops.

I think Mr. Thiele chose the wrong date. What he writes in his book it should be the Dat. entry from the bottom part of the card. It is no big thing since his date is the day the finished glass elements are handed over to the workshops that build and assemble the lenses.

There are some uncertainties. The card has enough space so the grinding department could hand over 2 different calculations in one batch. The purpose of those cards is to keep track of an order. But for me this card does loose control of the order easily and it is odd that the same date sometimes should mean start of and sometimes end of. I talk about the Dat. entry. In the top part the Dat. is from the grinding department and means end of. In the bottom part it is from the workshop department and means start of. That is odd.

What bugs me is that there is no control over how many lenses where assembled at this card. I would expect that at the bottom part the Dat. field is used as date of the last finished lens. Otherwise there would be no control over if the order is fulfilled or not. But since the Skizze vom entry hints to a later design date this Dat. field obviously is used as start of production date.

Did I miss something?

Räuber

Established

Why I argue in all length about this topic is because the Zeiss production process is almost unknown today. I could not find any description about it. Even this sample card only sheds a little light on it and leaves more questions than answers. But why does it matter? Because it might answer some strange effects that can be seen with the finished lenses.

As a collector or photograph picking one Sonnar lens in 90% of all cases is safe if you stay away from the war time and post war CZJ ones. But even then there is a chance that your Sonnar lens is not what it seems. More than once I picked a Sonnar lens by its design and then found out that it is out-of-time when checking the serial number. An out-of-time lens is one that did not match the other lenses in its serial number batch. Some Opton-Zeiss examples:

My interpretation of this out-of-time lenses is that some lenses where send back to the production to fix them. If the damage was to severe than the whole lens was replaced with a current one with the old serial number (case 1). For others they might reuse the housing and only replaced the glass elements and put the serial number of the current donator lens on the repaired lens (case 2). This might be more or less a problem with Opton lenses as this can mainly found in their production runs.

Another issue found with Opton-Zeiss is that some design changes where not introduced with clear borders. When they changed the number of aperture blades from 12 to 11 for their Sonnar 50mm F/1.5 they did this with painting the filter rim black (before silver). Unfortunately some silver rim lenses ended up with 11 aperture blades and some black ones with 12 aperture blades. So better check before buying one if the number of blades match the design (if you care). This shows me that at that time they used the parts for old and new design in parallel.

Most of the design changes from CZJ where clean (as far as I can tell). So maybe they used a different approach to fit the parts to the glass. There are some creeping changes with the nickel Sonnars with black painted ring though. It seems they started adding chrome finish to parts of the lens or the body so in the end some aperture rings where chrome or the lens body that was previously nickeled.

My feeling when looking at the Fertig. dates from Mr. Thieles Nummernbuch is that producing a lens took a long time. At the beginning 100 lenses maybe needed one month but later 500. Unfortunately the sample card does not give answer to the question how long does it take to grind the glass, produce all the parts of the lens and assemble it. It does not answer the question if design changes could appear within a production batch and if those changes where applied accurately. Looking at the finished lenses I can tell you that design changes where made within batches too.

As a collector or photograph picking one Sonnar lens in 90% of all cases is safe if you stay away from the war time and post war CZJ ones. But even then there is a chance that your Sonnar lens is not what it seems. More than once I picked a Sonnar lens by its design and then found out that it is out-of-time when checking the serial number. An out-of-time lens is one that did not match the other lenses in its serial number batch. Some Opton-Zeiss examples:

- 1.016.943, name ring = Carl Zeiss Sonnar 1:1,5 f=50mm Nr, filter rim=black,

- ZO batch=1953, 6700 copies

- batch name ring=Zeiss-Opton Sonnar 1:1,5 f=50mm T Nr

- batch filter rim=black

- 851.917, name ring = Zeiss-Opton Sonnar 1:1,5 f=50mm T Nr, filter rim=silver

- ZO batch= unknown

- batch name ring = Zeiss-Opton Sonnar 1:1,5 f=50mm T Nr

- batch filter rim=black

My interpretation of this out-of-time lenses is that some lenses where send back to the production to fix them. If the damage was to severe than the whole lens was replaced with a current one with the old serial number (case 1). For others they might reuse the housing and only replaced the glass elements and put the serial number of the current donator lens on the repaired lens (case 2). This might be more or less a problem with Opton lenses as this can mainly found in their production runs.

Another issue found with Opton-Zeiss is that some design changes where not introduced with clear borders. When they changed the number of aperture blades from 12 to 11 for their Sonnar 50mm F/1.5 they did this with painting the filter rim black (before silver). Unfortunately some silver rim lenses ended up with 11 aperture blades and some black ones with 12 aperture blades. So better check before buying one if the number of blades match the design (if you care). This shows me that at that time they used the parts for old and new design in parallel.

Most of the design changes from CZJ where clean (as far as I can tell). So maybe they used a different approach to fit the parts to the glass. There are some creeping changes with the nickel Sonnars with black painted ring though. It seems they started adding chrome finish to parts of the lens or the body so in the end some aperture rings where chrome or the lens body that was previously nickeled.

My feeling when looking at the Fertig. dates from Mr. Thieles Nummernbuch is that producing a lens took a long time. At the beginning 100 lenses maybe needed one month but later 500. Unfortunately the sample card does not give answer to the question how long does it take to grind the glass, produce all the parts of the lens and assemble it. It does not answer the question if design changes could appear within a production batch and if those changes where applied accurately. Looking at the finished lenses I can tell you that design changes where made within batches too.

JakobN

JakobN

I still believe we see the whole production process here starting with the indication of what computation to use and some Änderungen/changes, r means radius of curvature and b means thickness. My guess is that these changes were made to compensate for variations in the optical properties of the different batches of glass available.Very interesting. I never bothered to investigate the sample of production card but maybe we can learn something from it.

View attachment 4824795

This cards are made to take an order for one lens and than document all phases of production until the finished lenses are delivered.

There are some interesting findings with this card. The diameter of the 6th glass element was corrected. It only took 3 days to fetch the grinded glass for 400 lenses. I think they might have a pile of finished ones already and only pack the requested number.

- the order is for 400 Sonnar 5cm F2

- the serial number range is that of the 8th batch of the F2 Sonnar

- the order was received at Tuesday 13.12.32

- on 14.12.32 the order arrived at department Ko Pho (Konstruktion Photo? construction photo?)

- on Friday 16.12.32 the order arrives at department FBB (F-Betriebsbüro, frame-operations office?)

- on Monday 19.12.32 the order arrives at department OBB (O-Betreibsbüro, optics-operation office?)

- 400 finished kits of grinded Sonnar lenses are handed out (thats the date from Thiele Nummernbuch)

- on 20.12.32 the manufacturing of 400 Sonnar lenses is started (this is the date that belongs in Thiele Nummernbuch)

Interestingly the date for Pho Fa (Photo Fasserei, photo assembly) is missing. But we know that all lenses where assembled.

The most interesting thing for me is the Skizze vom entry. It says 5.1.1933 and that means this is some weeks after production of the lenses started. Skizze vom means sketch from. It means the sketch with the details how the lens is constructed was provided after the start. This is in line with what can be observed online. The design of the Sonnar 5cm F2 changed from batch 7 to batch 8. For example the engraved F-number switched from F22 to F16. So they did not use the old sketch but a new sketch was handed the lens workshops.

I think Mr. Thiele chose the wrong date. What he writes in his book it should be the Dat. entry from the bottom part of the card. It is no big thing since his date is the day the finished glass elements are handed over to the workshops that build and assemble the lenses.

There are some uncertainties. The card has enough space so the grinding department could hand over 2 different calculations in one batch. The purpose of those cards is to keep track of an order. But for me this card does loose control of the order easily and it is odd that the same date sometimes should mean start of and sometimes end of. I talk about the Dat. entry. In the top part the Dat. is from the grinding department and means end of. In the bottom part it is from the workshop department and means start of. That is odd.

What bugs me is that there is no control over how many lenses where assembled at this card. I would expect that at the bottom part the Dat. field is used as date of the last finished lens. Otherwise there would be no control over if the order is fulfilled or not. But since the Skizze vom entry hints to a later design date this Dat. field obviously is used as start of production date.

Did I miss something?

I haven't tried to decode the abbreviations of the different ABT./departments in the factory.

I didn't write anything about the lower half of the card because I do not know exactly what it means. These cards also have a back side, a few examples can be seen in "Zeiss and Photography" and one is 1631201 - 1631500. These 300 Sonnar 2/8.5 cm were finished in 12 batches of 25 pieces between june 7 and december 4 although the lenses were ready january 18, but there is a lot there that I cannot decode. The lower half of the front of the card probably describes an intermediate production step. I never had a Sonnar 8.5 apart but for instance in a collapsible Sonnar 2/5 the 3 lens groups each sit in their own mount and these are then finally assembled in the barrel.

TenEleven

Well-known

Very insightful, one small thing I can add is that the mounting of the glass into the lens tube changed several times over the life of the post-war (Opton, later Carl Zeiss) lenses. The silver lenses have all elements fitted into brass mounts including even the front element.Why I argue in all length about this topic is because the Zeiss production process is almost unknown today. I could not find any description about it. Even this sample card only sheds a little light on it and leaves more questions than answers. But why does it matter? Because it might answer some strange effects that can be seen with the finished lenses.

As a collector or photograph picking one Sonnar lens in 90% of all cases is safe if you stay away from the war time and post war CZJ ones. But even then there is a chance that your Sonnar lens is not what it seems. More than once I picked a Sonnar lens by its design and then found out that it is out-of-time when checking the serial number. An out-of-time lens is one that did not match the other lenses in its serial number batch. Some Opton-Zeiss examples:

Those are authentic Zeiss lenses and nobody cheated here. But the first one uses a design that was later introduced and the second example used a design that was not in production at the time. You can not tell the difference of other valid Sonnar lenses. But looking at the serial number it can be seen that this lens should was probably build to another time but got a new name ring with the serial number of another batch.

- 1.016.943, name ring = Carl ZeissSonnar 1:1,5 f=50mm Nr, filter rim=black,

- ZO batch=1953, 6700 copies

- batch name ring=Zeiss-Opton Sonnar 1:1,5 f=50mm T Nr

- batch filter rim=black

- 851.917, name ring = Zeiss-Opton Sonnar 1:1,5 f=50mm T Nr, filter rim=silver

- ZO batch= unknown

- batch name ring = Zeiss-Opton Sonnar 1:1,5 f=50mm T Nr

- batch filter rim=black

My interpretation of this out-of-time lenses is that some lenses where send back to the production to fix them. If the damage was to severe than the whole lens was replaced with a current one with the old serial number (case 1). For others they might reuse the housing and only replaced the glass elements and put the serial number of the current donator lens on the repaired lens (case 2). This might be more or less a problem with Opton lenses as this can mainly found in their production runs.

Another issue found with Opton-Zeiss is that some design changes where not introduced with clear borders. When they changed the number of aperture blades from 12 to 11 for their Sonnar 50mm F/1.5 they did this with painting the filter rim black (before silver). Unfortunately some silver rim lenses ended up with 11 aperture blades and some black ones with 12 aperture blades. So better check before buying one if the number of blades match the design (if you care). This shows me that at that time they used the parts for old and new design in parallel.

Most of the design changes from CZJ where clean (as far as I can tell). So maybe they used a different approach to fit the parts to the glass. There are some creeping changes with the nickel Sonnars with black painted ring though. It seems they started adding chrome finish to parts of the lens or the body so in the end some aperture rings where chrome or the lens body that was previously nickeled.

My feeling when looking at the Fertig. dates from Mr. Thieles Nummernbuch is that producing a lens took a long time. At the beginning 100 lenses maybe needed one month but later 500. Unfortunately the sample card does not give answer to the question how long does it take to grind the glass, produce all the parts of the lens and assemble it. It does not answer the question if design changes could appear within a production batch and if those changes where applied accurately. Looking at the finished lenses I can tell you that design changes where made within batches too.

The front element is the first one to lose the brass mount and the rear element is the last. However I have two late (Serials of 1.863xxx and 1.888xxx) Carl Zeiss 1.5 Sonnar where none of the elements are mounted in a holder anymore and the elements are just pushed into the tube that also holds the aperture.

Not only are these late-term lenses more prone to separation but at least for the tiny batch that I have tested (three in total - so basically anecdotal evidence) I found that they seemed to perform worse than mid-term "Carl Zeiss" labelled lenses in the 1.1-1.6million range. Perhaps Zeiss just wanted to be done with the Contax at this point...

They did however introduce some interesting and useful late-term changes (such as platinum finder, a spring which prevents the take-up spool from falling out during loading) to the Contax IIa, so who knows.

Räuber

Established

Could someone be so kind and provide me a sample of a card with back and front from the books? I did not know that there is a backside. But this would explain my issues I have with the cards only knowing the front side.These cards also have a back side, a few examples can be seen in "Zeiss and Photography" and one is 1631201 - 1631500. These 300 Sonnar 2/8.5 cm were finished in 12 batches of 25 pieces between june 7 and december 4 although the lenses were ready january 18, but there is a lot there that I cannot decode.

Räuber

Established

I did notice this too. I have not made a list but finding a Carl Zeiss Sonnar 50mm F/1.5 with serial > 1.885.000 and no separation is difficult. Without your information I thought it was a sign of missing quality in the optics department. But interesting to hear that they have changed the internal lens mounting that caused the issue. Did those changes effect the weight of the lens?Not only are these late-term lenses more prone to separation but at least for the tiny batch that I have tested (three in total - so basically anecdotal evidence) I found that they seemed to perform worse than mid-term "Carl Zeiss" labelled lenses in the 1.1-1.6million range. Perhaps Zeiss just wanted to be done with the Contax at this point...

Another interesting point is that both ZO and CZJ stopped production of all Sonnar 50 lenses 1959/1960. Not only Contax but all the Cine versions and special purpose ones as well.

About the late term changes. You have to keep in mind that Zeiss consists of different departments with independent goals. Maybe the camera department was more eager to win the competition with its rangefinder Contax camera than the lens department at the end of the 50ies.

furcafe

Mentor

Sorry to find this thread so late (haven’t been on RFF that much in the last few years), but I remember that lens. Very cool. Didn’t know at the time that the side had been filed down to fit on an M3.lukx, I know that Sonnar B and RFF member furcafe have taken photos with the 1933 lens on Leica cameras. Pretty sure that furcafe used a film camera, too. I recall seeing furcafe's pics on one of his photo accounts (possibly flickr) and he had done some good work in a concert venue with the old lens. Furcafe is a really good photographer.

For those curious, here’s a link to most of the few photos I was able to make w/it before I reluctantly returned it: Flickr Search — “carlzeissjena5cm15sonnarltmexperimentalc1933”

Last edited:

boojum

Mentor

Sorry to find this thread so late (haven’t been on RFF that much in the last few years), but I remember that lens. Very cool. Didn’t know at the time that the side had been filed down to fit on an M3.

For those curious, here’s a link to most of the few photos I was able to make w/it before I reluctantly returned it: Flickr Search — “carlzeissjena5cm15sonnarltmexperimentalc1933”

Much goes well with the M9.

TenEleven

Well-known

I did notice this too. I have not made a list but finding a Carl Zeiss Sonnar 50mm F/1.5 with serial > 1.885.000 and no separation is difficult. Without your information I thought it was a sign of missing quality in the optics department. But interesting to hear that they have changed the internal lens mounting that caused the issue. Did those changes effect the weight of the lens?

Another interesting point is that both ZO and CZJ stopped production of all Sonnar 50 lenses 1959/1960. Not only Contax but all the Cine versions and special purpose ones as well.

About the late term changes. You have to keep in mind that Zeiss consists of different departments with independent goals. Maybe the camera department was more eager to win the competition with its rangefinder Contax camera than the lens department at the end of the 50ies.

I guess it could be that as well. It may very well be a compound issue as Carl Zeiss famously changed the lens glue from Canada Balsam to a synthetic epoxy sometime after losing the "Opton" in the name. That plus - I am guessing here - increased mechanical and thermal stresses due to being direct mounted? And then perhaps finally also flagging quality.

Unrelatedly, late term S-Mount Nikkor 50s also have this issue. Separation is much more common in these than even the 1949 ones. I fee

I would have a guess that by 1959/1960 the lenses were largely superseded and the two cemented triplets were very costly to manufacture. The 85/2 (Opton variant) has also three cemented triplets but unlike the 50ies easily held its own. Even by today's standards that lens is a stunning performer.

Yeah good point. There is also penty of (pre war) documented rivalry between various factions inside Zeiss. Jena was not very eager to be making only Sonnar lenses which had been developed by Bertele, an outsider. They were very interested in making the Biotar, which their "own guy" Willi Merte had designed.

Regarding the weight - I have never weighted my lenses and sadly sold on most of my very late Sonnars for the reasons stated above. (Not as good performance as their peers, easy to seperate even if they are nice now.) But, luckily I kept one. So without further ado:

- Opton Sonnar Silvernose 50/1.5 - 60.xxxx - 166grams

- Opton Sonnar Blacknose 50/1.5 - 104.xxx - 157grams

- Opton Sonnar Blacknose 50/1.5 - 105.xxx - 157grams

- Carl Zeiss Sonnar BNose 50/1.5 - 1.1mil - 155grams

- Carl Zeiss Sonnar BNose 50/1.5 - 1.6mil - 154grams

- Carl Zeiss Sonnar BNose 50/1.5 - 1.88mil - 151grams

My kitchen scale is certainly not the most accurate, but I think the trend-line is obvious.

Räuber

Established

Here are 2 examples of those late term separation issues:I guess it could be that as well. It may very well be a compound issue as Carl Zeiss famously changed the lens glue from Canada Balsam to a synthetic epoxy sometime after losing the "Opton" in the name. That plus - I am guessing here - increased mechanical and thermal stresses due to being direct mounted? And then perhaps finally also flagging quality.

Unrelatedly, late term S-Mount Nikkor 50s also have this issue. Separation is much more common in these than even the 1949 ones. I fee

I would have a guess that by 1959/1960 the lenses were largely superseded and the two cemented triplets were very costly to manufacture. The 85/2 (Opton variant) has also three cemented triplets but unlike the 50ies easily held its own. Even by today's standards that lens is a stunning performer.

Ebay 1.888.701

Ken Rockwell 1.889.158

Yes, the cemented triplets where very expensive to make and slowly where superseded by other designs. But the show stopper was the rise of the SLR camera. SLR killed the RF concept. Not only Zeiss dropped the RF manufacturing. It was an international trend and the German industry was starting to trail the Japanese manufacturers here.

The Sonnar design is not usable on SLR cameras. The flange distance is to short for using it on an SLR. You can use it on a mirrorless though. But if you need a mirror you use a Planar design instead. And so with the rise of the SLR the Sonnar design was scrapped.

Coldkennels

Barnack-toting Brit.

I love the fact that ol' Rockwell is "reviewing" the 50/1.5 Sonnar as if his very poor condition one is representative of the image quality of a decent Sonnar. Oh, Ken. Never change.

lukx

Well-known

Also his facts are awfully wrong. The 1.5 was not introduced in 1937, but 1932. Also, they were not initially marked Carl Zeiss, but Carl Zeiss Jena. Coatings did not emerge only after the war – and so on...I love the fact that ol' Rockwell is "reviewing" the 50/1.5 Sonnar as if his very poor condition one is representative of the image quality of a decent Sonnar. Oh, Ken. Never change.

lukx

Well-known

I recently acquired this 270* series wartime rigid Sonnar 5cm f2. Only the front element seems to be coated, at least the rear doublet isn't. Coating is not in the best shape and there is some haze inside the triplet group in front of the aperture that I cannot clean. It's between the glass elements.

The mount/outer barrel is interesting, it's heavy – definitely not aluminium – and uses some kind of thread adapter/step down ring to fit the optical block. I haven't seen this kind of late serial rigid 5cm before. I assume it's a lens block from a collapsible lens that was adapted into a rigid shell, possibly sourced from a soviet lens...?!

The main issue is that the lens won't mount. Not on my Contax iia, not on my various Amedeo adapters. The lens was definitely used, but I don't know how anyone would have mounted it. From what I can tell, the guiding rails of the mount are machined too thick. This would be difficult for me to file into shape, so the lens is basically a paper weight. Luckily it was only 65€.

The mount/outer barrel is interesting, it's heavy – definitely not aluminium – and uses some kind of thread adapter/step down ring to fit the optical block. I haven't seen this kind of late serial rigid 5cm before. I assume it's a lens block from a collapsible lens that was adapted into a rigid shell, possibly sourced from a soviet lens...?!

The main issue is that the lens won't mount. Not on my Contax iia, not on my various Amedeo adapters. The lens was definitely used, but I don't know how anyone would have mounted it. From what I can tell, the guiding rails of the mount are machined too thick. This would be difficult for me to file into shape, so the lens is basically a paper weight. Luckily it was only 65€.

Last edited:

Share:

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.